Feed rate and direction of cutter pathġ3 L X+60 Y+35 FMAX M3. Second side length of pocketġ1 CYCL DEF 4.6 F100 DR+RADIUS 0. First side length of pocketġ0 CYCL DEF 4.5 Y+40. Pecking depth and feed rate for peckingĩ CYCL DEF 4.4 X+80. Milling depthĨ CYCL DEF 4.3 PECKG –4 F80. Note: BLK FORM has been changed!Ħ CYCL DEF 4.1 SET UP –2. Slot length and first milling direction (+)Ģ0 CYCL DEF 3.5 X+10. Pecking depth, feed rate for peckingġ9 CYCL DEF 3.4 Y+80. Milling depthġ8 CYCL DEF 3.3 PECKG –5 F80. Setup clearanceġ7 CYCL DEF 3.2 DEPTH –15. Slot parallel to Y-axisġ6 CYCL DEF 3.1 SET UP –2. Pre-positioning in Z, cycle callġ5 CYCL DEF 3.0 SLOT MILLING. Approach starting position, spindle onġ4 L Z+2 F1000 M99. Slot length and first milling direction (–)ġ0 CYCL DEF 3.5 Y+10. Pecking depth, feed rate for peckingĩ CYCL DEF 3.4 X–50. Milling depthĨ CYCL DEF 3.3 PECKG –5 F80. Slot parallel to X-axisĦ CYCL DEF 3.1 SET UP –2. Pre-positioning in Z, cycle callĥ CYCL DEF 3.0 SLOT MILLING. Pre-positioning, spindle on clockwiseġ2 L Z+3 FMAX M99. Approach tool change positionġ1 L X+50 Y+20 FMAX M3. Calculate Y coordinateĦ CYCL DEF 2.1 SET UP –3. Calculate X coordinateĥ1 FN3: Q22 = +Q22 * +Q4. End of subprogram for milling the ellipseĤ9 FN3: Q21 = +Q21* + Q3. Move to next pointģ9 FN 12: IF +Q37 LT +Q7 GOTO LBL 1. Call subprogram for calculating the points of the ellipseģ8 L X+Q21 Y+Q22 R0 FQ11 M. Plunge to milling depth at plunging feed rateģ5 FN1: Q36 = +Q36 + +Q35. Rapid traverse in Z to setup clearanceģ3 L Z–Q9 R0 FQ10 M. Move to start point in the planeģ2 L Z+Q12 R0 F MAX M. 1113967-01 Heidenhain TNC Keyboard 1113967 01 for TNC Programming Station TNC 640 TNC 620 TNC 320 iTNC 530 with softkeys TNC640 TNC620 TNC320 iTNC530. Call subprogram for calculating the points of the ellipseģ1 L X+Q21 Y+Q22 R0 F MAX M03. Call subprogram for calculating the points of the ellipseģ0 CALL LBL 11 REP. Set counter for milled stepsĢ9 FN0: Q37 = +0. Current angle for calculation =Ģ8 FN0: Q36 = +Q5. Calculate angle increment (end angle to start angleĢ7 FN4: Q35 = +Q35 DIV +Q7. Activate rotation, if Q8 is loadedĢ6 FN2: Q35 = +Q6 – +Q5. Shift datum to center of ellipseĢ5 CYCL DEF 10.1 ROT +Q8. Retract in Z, end of main programĢ3 CYCL DEF 7.2 Y+Q2. Call subprogram ellipseġ9 L Z+20 R0 F MAX M02. Number of calculating stepsĨ FN 0: Q8 = +0. Y coordinate for center of ellipseģ FN 0: Q3 = +50. X coordinate for center of ellipseĢ FN 0: Q2 = +50. CLEARANCE HEIGHTĥ L X-20 Y+40.AUXILIARY POINT (R0)Ĩ APPR LCT X+5 Y+40 R3 RL F300.CONTOUR STARTING POINTġ8 L Y+40.LAST CONTOUR POINT 19 DEP LCT X-20 Y+40 R3.AUXILIARY POINT (R0) 20 L Z+100 R0 F MAX M2.RETRACT TOOLġ FN 0: Q1 = +50. Mazak Training Fanuc Trainingĭon’t forget we offer training on all types of Mazak Machines and all Fanuc Controls 6m to 31i Oi old to young.2 BLK FORM 0.2 X+100 Y+100 Z+0.WORKPIECE BLANK DEFINITIONģ TOOL CALL 7 Z S2500.CALL TOOL DATA R4Ĥ L Z+100 R0 F9999. Services offered at CNC Training CentreĬNC Training on all controls and machines. We offer training on all types of CNC Machines and controls check em out. Heidenhain Training call David 07834 858 407

#Heidenhain programming how to

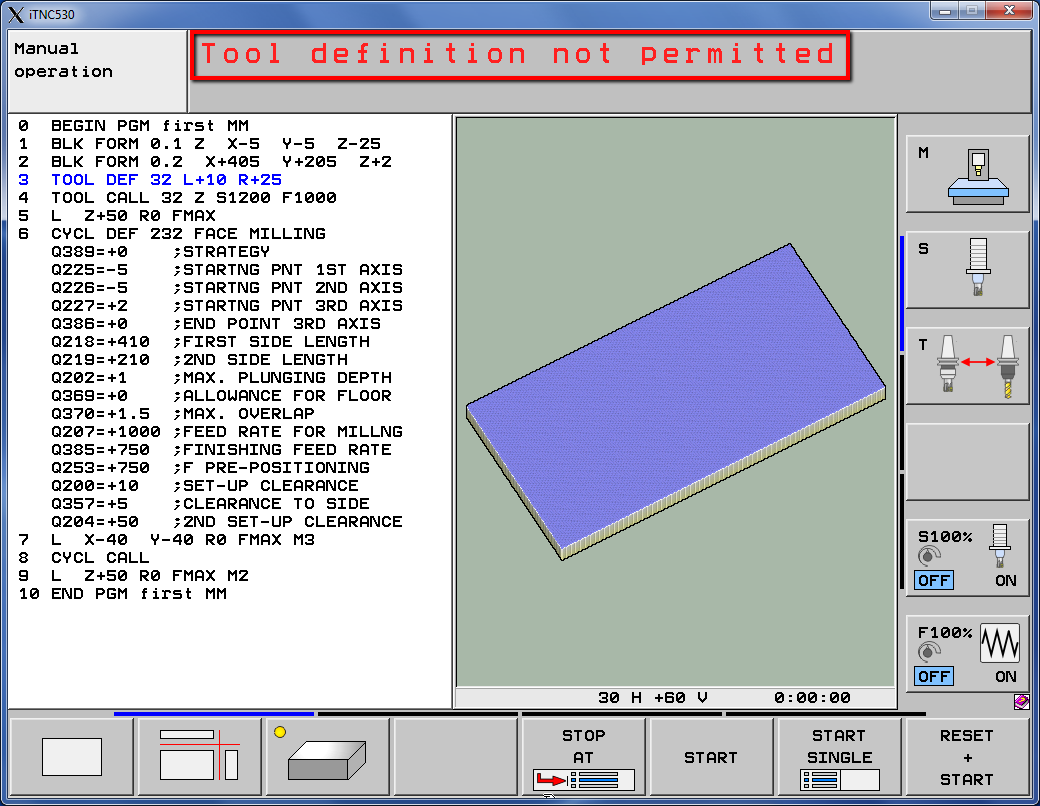

(3) This example shows how to use sections in Heidenhain Programmes.Ĭontact me if you are interested in learning Heidenhain Programmingĭon’t forget to watch my Tutorial Videos on YouTube This is how to use cutter compensation on both Heidenhain and Fanuc. (2) Here is another Heidenhain Programming Examples. End point and radius? This buttons for you .The drawing gives me the centre of the radius.The idea is you programme the same as your drawing. “Why would I want to do that sounds complicated”Īctually it ain’t. You can programme circular arc moves in four different ways on this control. (1) Here is an example of how to use the various arc commands on a Heidenhain control. The sizes, feeds and speeds, all sorts of stuff can be changed each time the programme runs. It means that you can control a programme externally. It’s ok it’s just me trying to be posh again. “Bloody hell what are they” I hear you say. It has a parametric programming function using Q defs. Don’t be fooled by this there is loads of new stuff lurking under the surface. Most of the buttons will look familiar if you worked on older controls and you come to the newer models. The problem with learning something quickly and easily is that lots of good features are missed.Īt the CNC Training Centre we hate to see things underused we are The Wombles of CNC Programming. It is a control that can be used on many levels and has some very sophisticated features.This is a control that can be learned quickly and easily.It has improved with age as more and more useful features get added.The control has been around for a long time and is fitted on many machines.

0 kommentar(er)

0 kommentar(er)